Even the tiniest hole in an exhaust system can affect the accuracy of a wideband gauge. We put that to the test on the engine dyno with an MTX-L Plus gauge and a set of drill bits.

In the world of automotive tuning, knowledge is horsepower. Gauges, loggers, and sensors galore provide the data to advance performance, solve problems, and prevent expensive engines from experiencing critical meltdowns. But, not all information is equal.

In the case of a wideband sensor, the purity of the exhaust flowing across its face is key to achieving an accurate air fuel ratio or lambda reading. Even the smallest exhaust leak can distort that, leading to false readings and corrupt data. Like a compass that doesn’t point North, bad wideband readings can nudge tuning efforts entirely in the wrong direction.

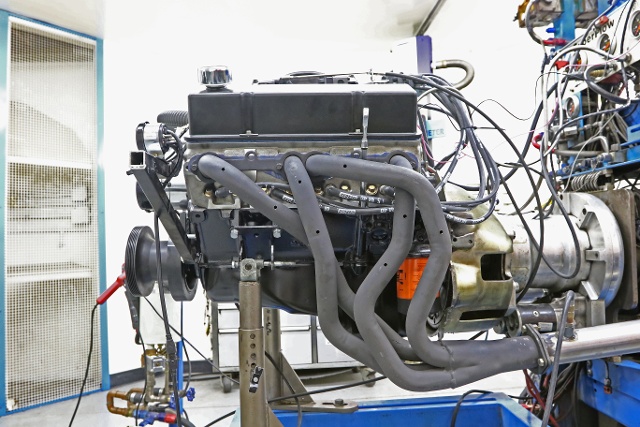

To illustrate the effects of a leaky exhaust, we headed down to the engine dyno at Westech performance with an Innovate MTX-L Plus–equipped small-block Chevy, a set of headers, and a Dewalt power drill.

We used an Innovate MTX-L Plus gauge as a guinea pig for our tests. It was mounted on a custom-fabricated bracket in the dyno cell.

How Does An O2 Sensor Work

To understand why an exhaust leak is so detrimental to O2 sensor (also known as a wideband sensor) performance, one must first understand how an O2 sensor works. A wideband sensor works by comparing the oxygen left in the exhaust after combustion to the sensor’s reference pump cell which is referencing the stoichiometric ratio of the fuel being burned. If the engine is burning fuel at its stoichiometric ratio, all of the oxygen is consumed during combustion. If the engine is running lean, there will be excess oxygen in the exhaust because there was not enough fuel present in the combustion chamber to completely burn it. In rich conditions, the opposite is true.

Now, should ambient air weasel its way into the exhaust stream, the amount of oxygen present in the sensor’s active environment is artificially increased. As such, the sensor will interpret it as a lean condition, assuming not enough fuel was present to burn the stowaway oxygen.

Before any testing could begin, we performed a free air calibration on our MTX-L Plus.This process references atmospheric conditions to provide the most accurate readings and can even accommodate for sensor wear. Click here for free air calibration instructions.

It’s no secret that an exhaust leak negatively impacts wideband accuracy, or that it will skew readings lean, but how big of a hole would cause a significant reading change remained untested.

Once at Westech, our 350ci small-block Chevy was bolted to the dyno and the MTX-LPlus wideband AFR gauge was wired up and mounted on the engine. A free air calibration was performed first to insure the most accurate readings, and the engine was run on the dyno to establish baseline data for the air fuel ratio curve.

Baseline Pull

MTX-L Plus Readings

Idle: 10.8

Light load (cruise): 13.0

WOT: 12.2

We made three pulls and averaged the results for each test. While certainly on the rich side, these are fairly typical numbers for a carbureted, performance pushrod engine with a large-duration camshaft. Knowing for sure what sort of AFR numbers our small-block generated, it was time to poke some holes and see just how upset our wideband sensor would get.

Test 1: Blown-Out Collector Gasket

MTX-L Plus Readings

Idle: 22.4

Cruise: 20.1

WOT: 15.1

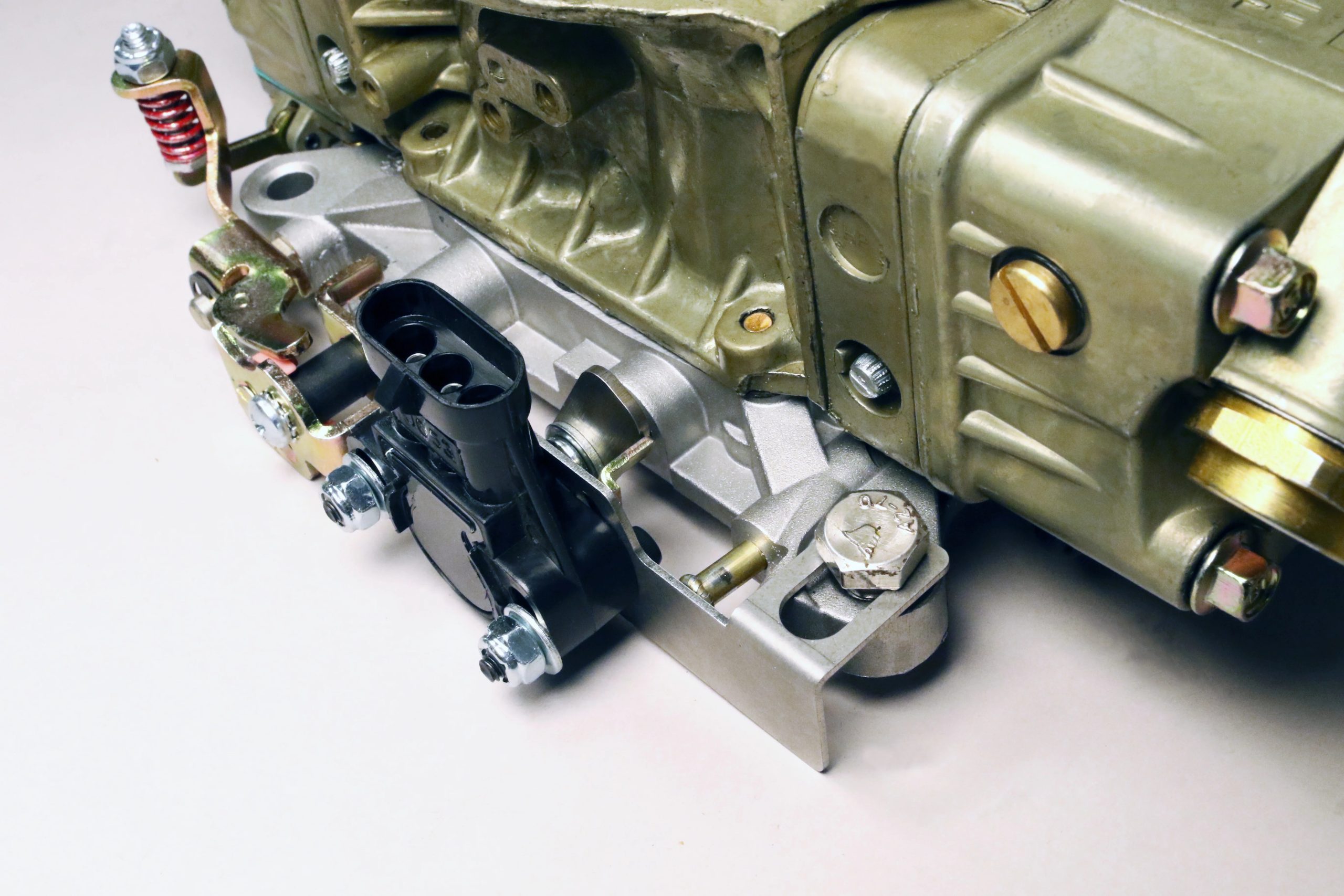

The first test was to fail the gasket in the exhaust collector. In many aftermarket applications, the O2 sensor is mounted behind a collector gasket. Being a large gasket, should it fail, the resulting gap is significant and has the potential to introduce a large amount of ambient air. To test the theory, Westech’s Steve Brulé loosened the 3/8in nuts on the collector slightly and fired up the engine.

Looking For A Gauge? See Innovate’s Full Product Line Here!

The initial AFR readings were unaffected, but that rapidly changed as the gasket burned and the gap between the collector’s flanges widened. In under a minute, the gauge’s readings were rendered completely useless at idle, reading 22.4 (full lean). At cruise, the reading was still approaching max lean, at 20.1, and WOT showed a still-lean 15.1. Obviously, these readings were not indicative of how the carbureted engine was running, only what the gauge was reading due to the massive exhaust leak.

Test 2: Header Gasket Failure

MTX-L Plus Readings

Idle: 15.3

Cruise: 14.1

WOT: 13.2

The next test, after replacing the collector gasket, was to loosen the header flange and let that gasket fail. In this test, only idle and cruise readings were affected. At WOT, the high exhaust velocity purged most ambient air and kept the reading fairly accurate.

The next most common gasket failure occurs at the header/exhaust-manifold flange next to the exhaust port. This is one of the hottest points in the exhaust system, and subsequently can cook gaskets pretty easily. Initial assumptions were that this failure point would induce even worse results than the flange gasket failure, however that proved not to be the case. All readings were within one to two points of the baseline pull. According to Brulé, the high pressure of the exhaust leaving the port was likely helping to purge any ambient air from the system.

Test 3: Poking Holes in Header Tubes

MTX-L Plus Readings

Idle: 17.4

Cruise: 16.3

WOT: 12.5

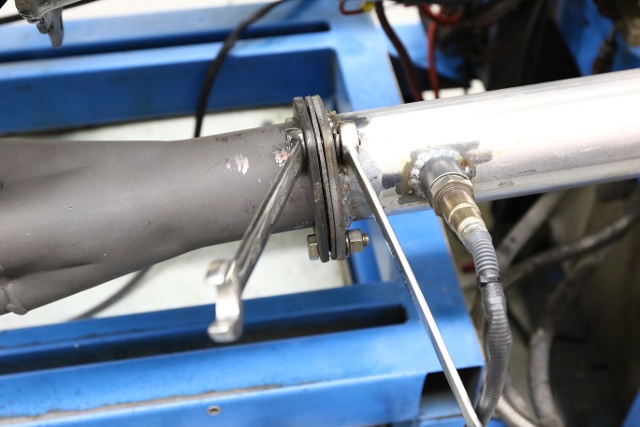

Brulé began by drilling one hole. He then continued to Swiss-cheese the header, taking readings in between drill sessions.

The final test of the day involved drilling 1/4in diameter holes in the header tubes– a size that rust or road damage could easily induce into a header. We started with one hole, then progressed to one per tube, absorbing a common trend. Idle and Cruise AFRs were negatively affected, registering about a quarter to half a point leaner with each new hole. However, even after getting a little drill happy and punching eight holes in the header, WOT mixture readings were still unaffected, as the high exhaust velocity in the individual header tubes was again able to purge the system, preventing ambient oxygen molecules from sneaking into the sensors readings.

Potential for EFI Disaster

As demonstrated, any sort of exhaust leak will provide inaccurate information and poor tuning intuition. But far worse things can happen in a closed loop fuel injection system. Our carbureted small-block is…well, dumb. It responds to the velocity of air flowing through its venturi and, through a system of precision drilled orifices, provides fuel to match. It does not actively respond to running conditions and is such unaffected by an exhaust leak. A fuel injection system, via a slew of sensors, including a wideband sensor, has the means to intelligently react to changes in combustion.

| Baseline | Blown Collector Gasket | Blown Header Gasket | Pinholes | |

| Idle AFR | 10.8 | 22.4 (+11.6) | 15.3 (+4.5) | 17.4 (+6.6) |

| Cruise AFR | 13.0 | 20.1 (+7.1) | 14.1 (+1.1) | 16.3 (+3.3) |

| WOT AFR | 12.2 | 16.3 (+4.1) | 13.2 (+1) | 12.5 (+.3) |

From the table above it is clear just how much an exhaust leak affects idle and cruise AFR readings. Considering an engine spends the majority of its time in these zones, this is a critical tuning issue.

When in “closed loop,” the ECU can detect a lean, or rich, condition and add/subtract fuel to compensate, bringing the observed AFR back in line. When an exhaust leak is present, the ECU can detect a false lean signal and respond incorrectly, adding fuel in an attempt to remedy the problem, but further exacerbate it. This is an especially big concern with the copious self-learning EFI systems flooding the aftermarket.

An undiagnosed exhaust leak can manifest as a huge problem, re-writing healthy fuel maps and making the car nearly un-drivable. As the dyno test showed, idle and cruise situations, where exhaust volume is lowest, are especially vulnerable areas. So, if you suspect your AFR gauge is reading uncharacteristically lean, whether you here the infamous “tick, tick, tick,” of an exhaust leak or not, your first move should be to check the pipes for pollution.

Want to learn more about AFR and other tuning tech? Check out these stories!